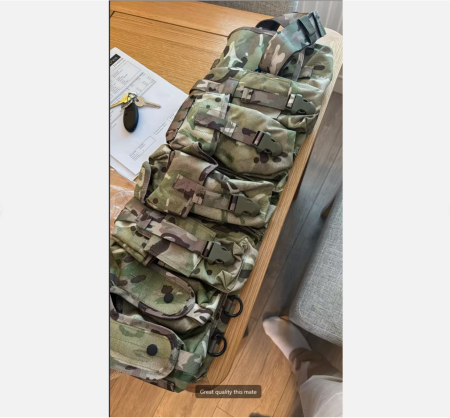

One of the most commonly asked questions is before purchase, is what exactly is this kit made from and the answer is MTP, 100% IRR 1000D Cordura Multicam compliant 305gsm fabric.

Soldiers on the front line need quality stuff made from the highest fabric materials which need to satisfy stringent requirements of durability and infra-red reflectiveness as well as being fit for the required end product; we source everything we use in our goods from the UK suppliers which have satisfied relevant criteria as well as passed certification and in some cases is already used in issued kit.

All our military kit is made from UK sourced fabrics from contracted MOD suppliers.

The fabric for example used in our webbing is MTP in 1000D Cordura, the very specs themselves can be seen here, just so you know it’s the best you can get.

FABRIC SPECS – MTP Multi Terrain Pattern

Description: Dyed woven 1100 decitex texturised nylon, pigmented polyurethane coated with a water repellent finish.

Fabric: Nominal 305gsm ± 5%, 1100 decitex texturised nylon, warp and weft.

Coating: Hydrolysis resistant polyurethane coating with anti-bacterial additive.

| Property | Test Method | Requirement | Typical Result |

| Weave | BS 2861 | Plain | Pass |

| Threads/cms | BS EN 1049-2 | Warp: 13.5 (min) Weft: 11.0 (min) |

14 11 |

| Mass (gsm): (a) Total (b) Base fabric (c) Coating |

BS EN ISO 2286 – 2 | 360 ± 25 305 ± 15 60 ± 10 | 360 – – |

| Width (cms) |

BS EN ISO 2286 – 1 | 148 | 152 |

| Tear strength | BS EN ISO 4674-1 Method A | Warp: 550N Weft: 525N |

700 650 |

| Tensile strength |

BS EN ISO 1421 Method 1 | Warp: 2800N (min) Weft: 2500N (min) |

2800+ 2500+ |

| Resistance to water penetration: (a) as received (b) after ageing |

BS EN 20811:1992 24hrs at 70°C at 95% humidity |

65cms 40cms | 90 60 |

| Cold crack |

BS 3424: Part 8 Method 10A | -20°C (max) | Pass |

| Blocking |

BS EN 25978 | No blocking | Pass |

| Abrasion resistance | After 2000 rubs with 80 grade emery cloth, fabric side should show no signs of abrasion | Pass | Pass |

| Colour fastness | BS EN ISO 105 | Requirement | Typical Result |

| a. To light (B02) | Each colour | 5 – 6 | Pass |

| b. To water (E01) | Change, across 3 test specimen colours | 4 – 5 | Pass |

| Staining, across 3 test specimen colours | 3 – 4 | Pass | |

| c. To sea water (E02) | Change, across 3 test specimen colours | 4 – 5 | Pass |

| Staining, across 3 test specimen colours | 4 | Pass | |

| d. To perspiration (E04) | Change, across 3 test specimen colours | 4 – 5 | Pass |

| Staining, across 3 test specimen colours | 3 – 4 | Pass | |

| e. To washing (C06) C2s@60°C after 1 wash | Change, across 3 test specimen colours | 4 – 5 | Pass |

| Staining, across 3 test specimen colours | 3 – 4 | Pass | |

| f. To rubbing (X12) | Dry | ||

| Across 3 test specimen colours | 4 – 5 | Pass | |

| Wet | |||

| Across 3 test specimen colours | 3 – 4Pass |